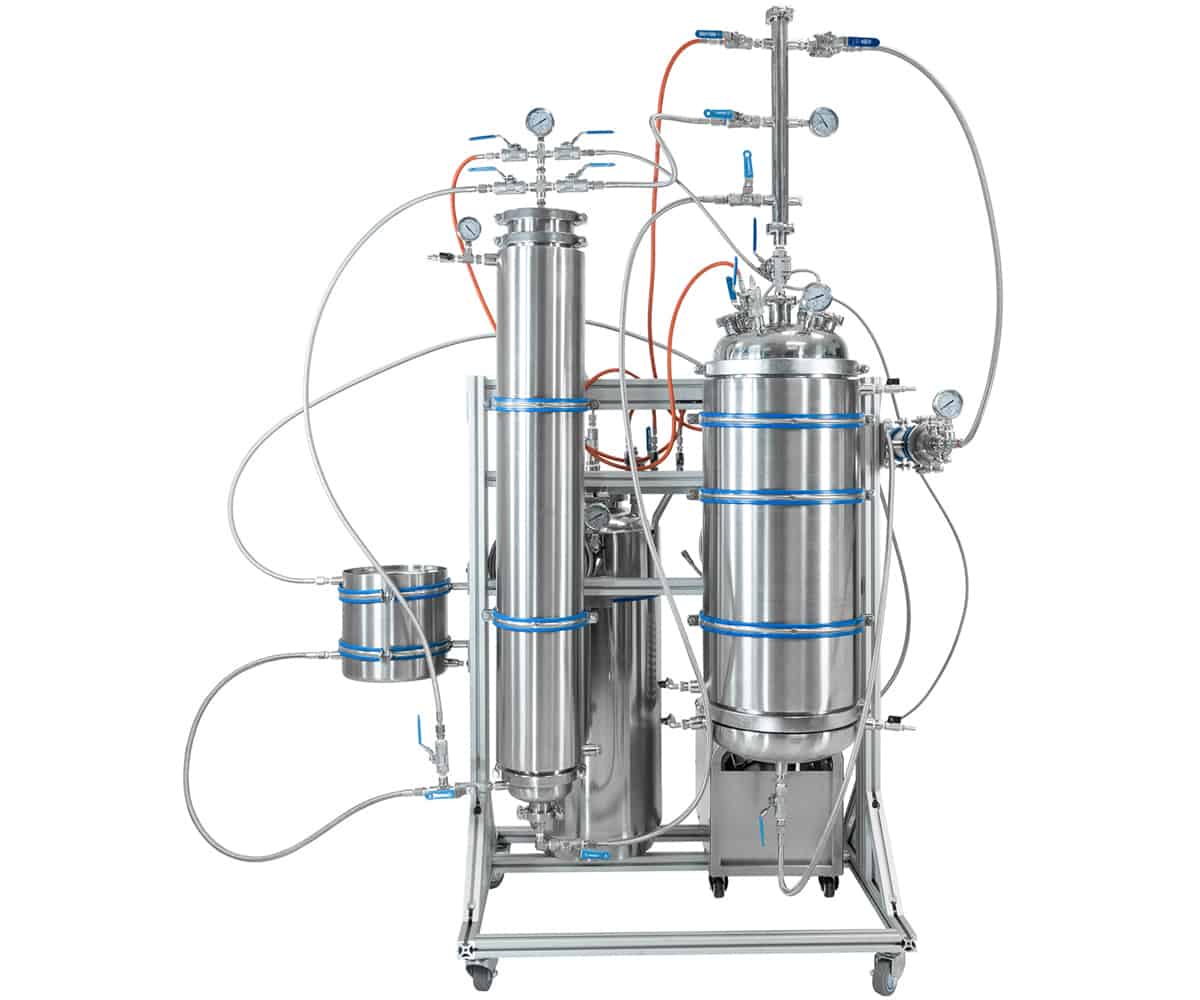

Description

The Mercurius system is a rack-mounted MK-V that is specifically built to be run actively. Bi-directional solvent input prevents channeling and ensures a full yield is achieved. The Mercurius system also features a CMEP-OL recovery kit standard. The CMEP-OL has a coil bypass built onto the output to re-loop hot vapors back to the top of the material column. This is used to pressurize the material column after extraction to clear/assist in recovering the column. Hot vapor loop features a coil that can be heated in a warm water bath to boost vapor pressure/temperature.

The Mercurius system features a recovery manifold that is also used as the overflow path when bottom filling. This allows the column to be recovered independently from the collection base. With this plumbing, the user can utilize the evaporative cooling properties of the extraction solvents. By injecting a small amount of solvent into a closed material column, slightly wetting the material, then recovering this solvent, the material is frozen once all solvent flips phase. This method, paired with an injection coil, ensures efficient dewaxing happens without excessive dry ice or expensive chilling units.

This system is entirely rack mounted, giving this highly efficient system a small footprint.

Features:

• Up to 10 lb material capacity

• Bi-directional solvent input

• Injection coil dewaxing

• Vacuum insulated material column

• Recovery manifold for base and column

• Hot vapor reloop for column recovery

• Active recovery with CMEP-OL

• Rack mounted jacketed base for temperature control circulation

• Collection base drain port with extract dispensing wand

• Condensing coil for efficient recovery

• Sight glasses on collection base

• 100 micron filtration built into gasket

• Rack mounting

• Stainless steel recovery tank

• Molecular sieve to remove moisture from LPG

• ½” recovery lines

Benefits:

• Rack mounting to prevent heavy lifting

• Maximum oil yield

• Efficient dewaxing

• Save money with solvent reclamation

• Little to no solvent loss per run

• Limited dry ice consumption

• Fast run and recovery times

Includes:

• Extruded aluminum rack with pipe hangers

• 12” x 30” jacketed collection base with drain port

• #100 stainless steel jacketed LP tank with internal condensing coil

• Solvent injection chilling coil

• 6” x 48” material column

• CMEP-OL recovery kit

• Stainless steel braided PTFE hoses

• Buna-N tri-clamp gaskets

• High pressure clamps

ADDITIONAL EQUIPMENT REQUIRED FOR OPERATION OF UNIT. THIS UNIT REQUIRES A VACUUM PUMP, DRY ICE, NITROGEN TANK WITH REGULATOR, AND HEATER CIRCULATOR TO FUNCTION.

It is also recommended to have a refrigerant scale to operate this unit. A chiller can be run with the recovery tank to aid recovery times.

A Pro Series 21 cfm (BVVPS212B) vacuum pump is recommended for this system.

Technical Specs:

Max Allowable Working Pressure: 150 PSI

Operating Temperature Range: -40F – 200F

304 Stainless Steel Construction

High Polish Interior

Solvent Capacity: 50 lbs

Reviews

There are no reviews yet.